YINGYANG MACHINING CENTRE

Professionalism is a driving force at YINGYANG and the company employs the newest technology to process the components of YINGYANG machine. YINGYANG is equipped with a lot of manufacturing facilities like Turning-milling machining center from Austria, Boring-milling machining center from Italy, Pentahedron Gantry machining center from Spain, Turning-milling machining center from Japan, plasma cutting machine and other CNC machines. For the quality inspection, YINGYANG also imported the latest European laser checking systems to ensure consistent quality and reliable manufacturing of components and machinery.

YINGYANG quality system is registered to ISO9001:2015 and implemented throughout the plant.

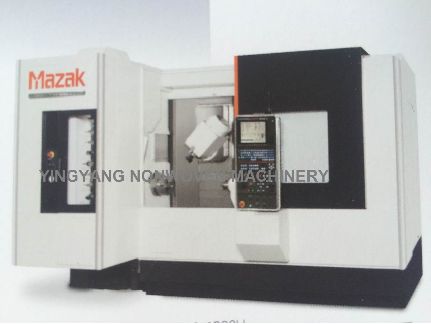

Japanese imported Yamazaki Mazak turn-milling compound

Mainly used for processing carding machine shaft sleeve, end cover; needle machine sealing cover.

Germany Zeiss three coordinate measuring instrument

Both high-precision measuring tool and contact three-dimensional coordinate detection technology, the use of high-speed scanning device for multi-point continuous detection, coordinate detection and shape detection combined.

follow-up CNC grinding machine

It is used for processing the spindle of the needle punching machine box, with high efficiency and high precision, which ensures the surface size accuracy, coaxiality and cylindricity of the roller to the greatest extent.

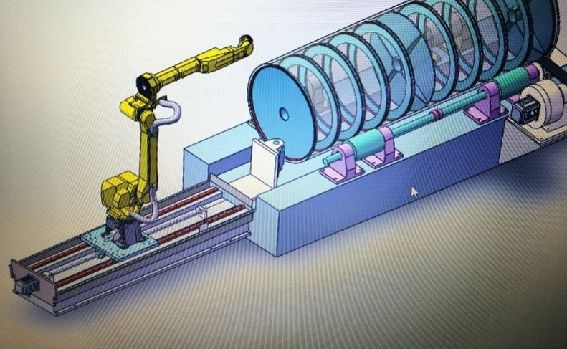

Fanaco robot automatic welding platform

Used for welding carding machine rollers, with high stability, good consistency, uniform and smooth welds, firm and reliable.

7 CNC gantry drill

It is used for punching needle plates and has the advantages of high precision, good stability and high speed.

CNC cylindrical grinder

Used for processing carding machine rollers. Ensure the roundness of the roller, the consistency of the diameter on the longitudinal section and the surface roughness.

10 m Gantry Machining Center

Used for processing needle machine frame, beam. Suitable for heavy parts processing.

Italy Pama boring and milling machining center

It is used for processing the box of the needle punching machine to ensure the accuracy of boring, the parallelism and verticality are within 3 wires, ensuring the high speed of the needle punching machine, less vibration, low noise, no oil leakage, stability and reliability.

2 CNC gantry machining centers

Main processing needle punching machine movable beam (aluminum beam)

Spain Nicolas automatic five-sided gantry machining center

Main processing: needle machine frame beam

WFL turn-milling compound machining center

Main processing: needle machine box spindle