Hard cotton oven

■Scope of application

Key words:

Product series:

- Product Description

-

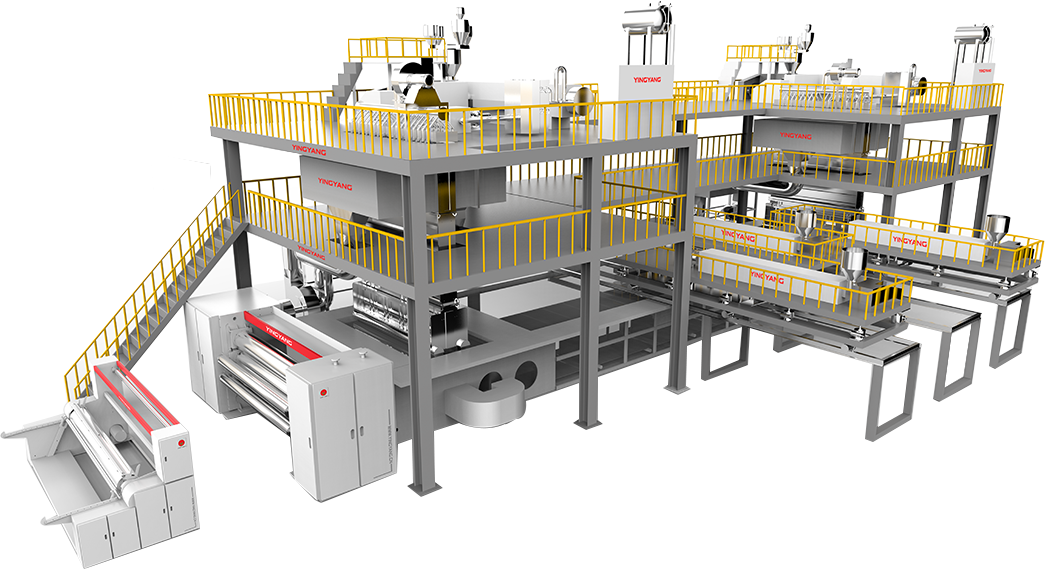

- Commodity name: Hard cotton oven

- Commodity ID: 1136721519561035776

Function

This machine is to thermally bond cotton web or non-woven semi-finished products containing low melting point fibers through hot air penetration to achieve a certain thickness and hardness.

Reach a certain thickness and hardness.Main Specifications

Working Width: ≤ 3800mm

Heating Room Length: 6 m, 8 m, 10 m Double Mesh Belt

Heating Set Temperature: ≤ 200 ℃.

Working speed: ≤ 20 m/min.

heating cycle mode: blow up and suck down, blow down and suck up and penetrate in sequence.

heating method: electric heating, burning natural gas heating, burning diesel heating.

Installed capacity: 62.4KW (electric heating power depends on the width and length of the oven).Features

Upper blowing and lower suction, lower blowing and upper suction alternately, so that the cotton wool is evenly heated and the surface is even.

●The burner is directly connected to the suction fan through a stainless steel pipe to improve the mixing effect of the heated air.

● The upper channel adopts Teflon soft connection to achieve good sealing effect during hot air circulation.●The unique insulation layer design makes it achieve the insulation effect and reduce heat loss.

Previous:

Next:

Previous:

Next:

Production line

Popular Product Line

Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!