Automatic pillow filling production line/stepping quilt production line, lining quilt production line

■Scope of application

Key words:

Product series:

- Product Description

-

- Commodity name: Automatic pillow filling production line/stepping quilt production line, lining quilt production line

Used in the production of wider staple fiber quilts, used in the production of quilts and other fiber-filled products. Cutting, metering and filling are automatically completed, and winding devices can be installed when necessary. The maximum output can produce 120 quilt cores per hour.

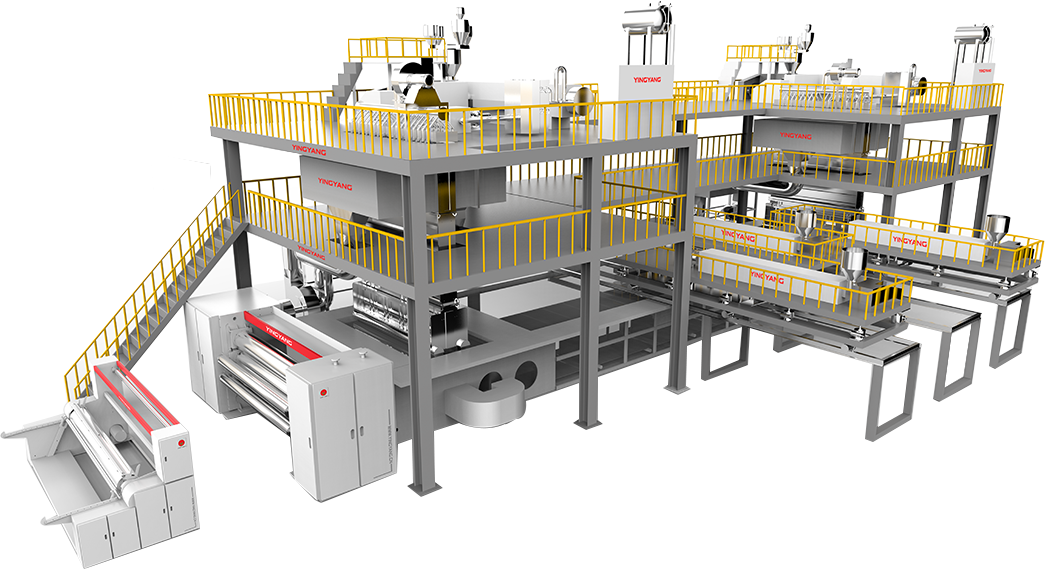

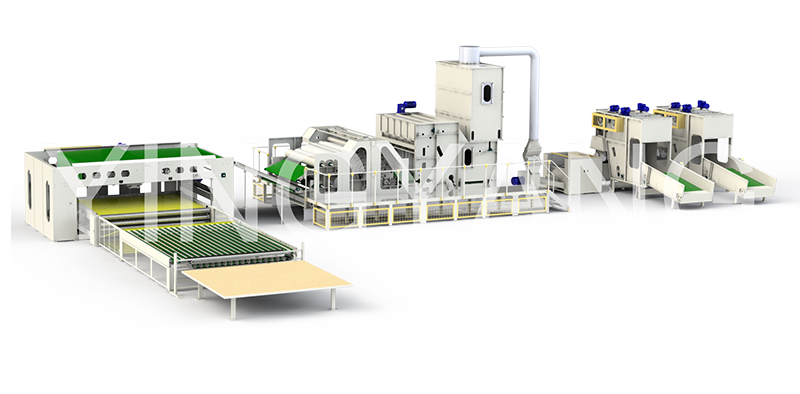

Quilt Production Line

Application and Technology:

is used to produce wider staple fiber quilts, used to produce quilts and other fiber filling products.

Cutting, metering and filling are automatically completed, and winding devices can be installed when necessary. The maximum output can produce 120 quilt cores per hour.Main specifications:

Raw materials are synthetic fibers such as polyester fibers, as well as natural fibers such as cotton, wool, bamboo fibers, and soybean fibers.

product net width 1500-3200mm

product weight 60-500g/㎡automatic filling production line

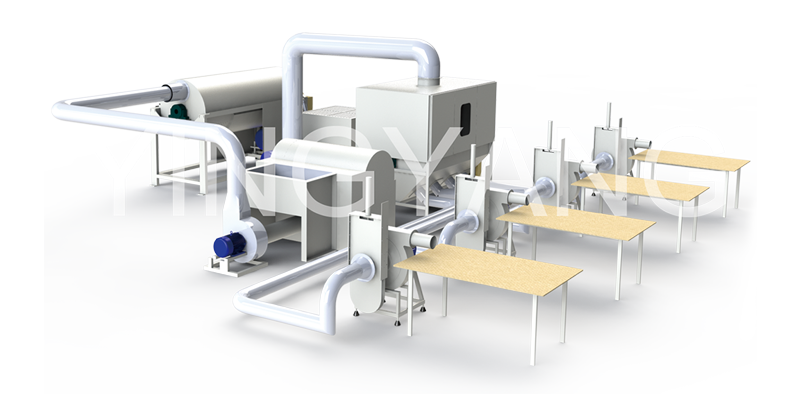

application and technology:

mainly includes opener, pearl cotton machine, cotton collection box, automatic pillow filling, etc. The automatic filling production line can be composed of various types of machines according to the products to be produced, fiber types and output. For fiber-filled pillows requiring high throughput, carding, cross-lapping, fiber metering systems are available. It can be made into 1) pearl cotton 2) open cotton 3) carded and filled pillows, which have high resilience and restorability. It can be used not only for pillows, but also for soft toys and other items.

Production line

Popular Product Line

Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!