SOFT THERMAL BONDING OVEN

■Scope of application

Key words:

DRYING & HEAT SETTING

Product series:

- Product Description

- Production Line process

- Operation Video

- Application

-

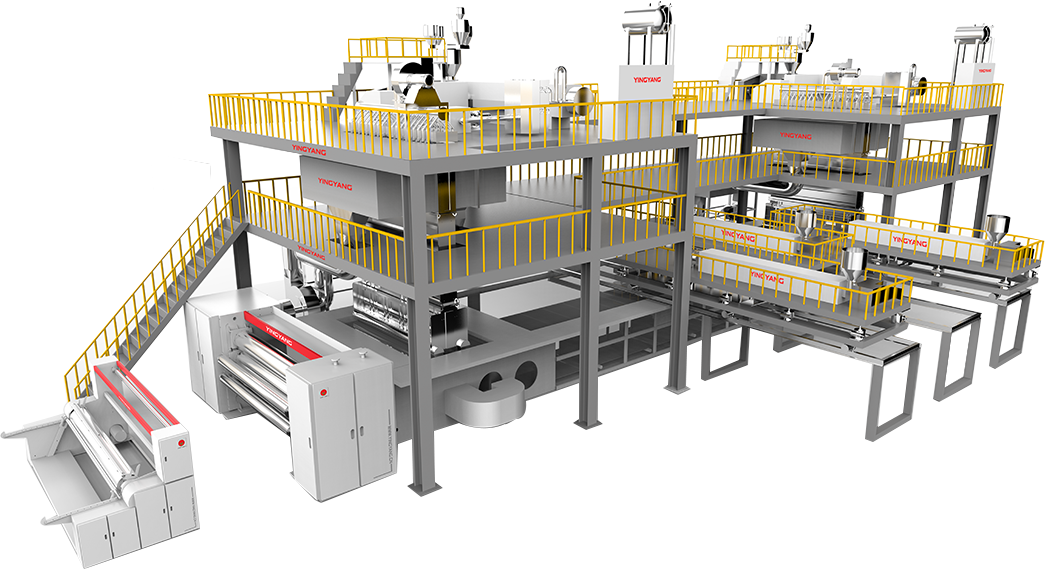

- Commodity name: SOFT THERMAL BONDING OVEN

This machine is used to thermal bond the web from cross lapper by melting the low melt fiber by hot air penetration.

FunctionThis machine is used to thermal bond the web from cross lapper by melting the low melt fiber by hot air penetration.Main SpecificationWorking width: ≤5000mmHeating Chamber Length: 6m, 8m, 10m, 12mSuitable product weight: 60-600gsmHeat setting temperature: ≤200℃Working speed: ≤25m/minStructure: single belt thermal-bonding ovenHeating source: hot oil circulation, gas burner heating, diesel oil burner heating, electricity heatingInstalled power: 17.2KW(Electricity heating power according to oven width and length)Characteristics●Compact design for heating chamber to achieve the best heat energy utilization.●Unique design for thermal insulation layer so as to achieve the best insulating result, reducing heat loss●The distance between upper air channel and conveyor belt can be automatically adjusted according to the thickness of the web.Key words:- soft wadding

- nonwoven oven

-

1.The specification of soft-thermal bonded oven is 310type *10 meter soft-thermal bonded oven output with 3 meter closed up web clamping cooling. The former 7 meters adopt up blowing and down suction, the eighth meter is counter blowing and web clamping. The ninth meter is warm keeping part and web clamping. The tenth and eleventh meter are down blowing cooling shape and web clamping. And the former 7 meter blowing channel can be lifted.

2. Material is delivered by Teflon mash belt, characterized by high-temperature resistance, corrosion resistance, pick resistance, bending and fatigue resistance and etc.

3. Hot air circulation system adopts the method of penetration by blowing from above and sucking from below. 2 fans and ventilation cavity and heat resource component form two independent setting zones.

4. Frame component: input and output frames and main frame. All the frames are welded with channel steel#10 and angle iron.

5. Attemperator is made of iron plate and rockwool, with good heat insulation.

-

Function

This machine is used to thermal bond the web from cross lapper by melting the low melt fiber by hot air penetration.

Previous:

Previous:

Production line

Popular Product Line

Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!